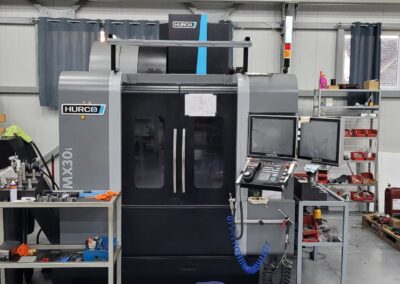

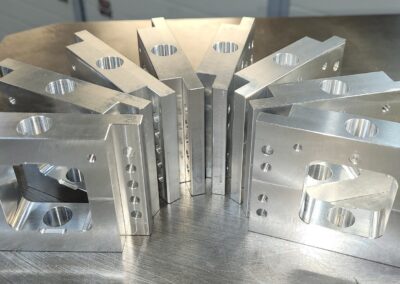

machining workshop

Progress

We are expanding the scale and quality of our services all the time by purchasing of new equipment.

Materials

Materials we work with are different grades of steel, non-ferrous alloys, polymers and many others.

Field of activity

Our Services

Cutting

The most of our raw materials are usually purchased as bars. The first step in the process is to cut them into smaller pieces. We are capable to cut raw material up to ⌀320mm.

Turning

The size of parts we can machine by turning is ⌀350x750mm.

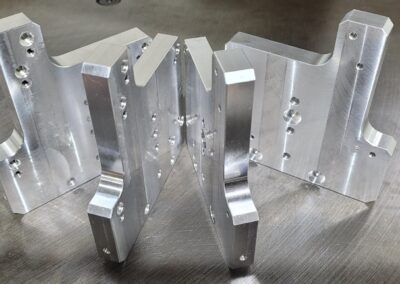

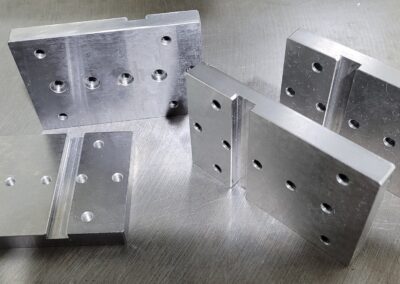

Milling

Our shop is equipped with CNC machining centers with a workspace of 700x500x600mm. The accuracy of machining is 0,01mm. We have all the tools needed to provide high quality parts, and all the gauges to check the dimensions according to the drawing.

Heat treatment

If required, the parts are heat treated. The results achieved are checked with a hardness tester. The hardness tester is calibrated by using certified test blocks.

Cylindrical grinding – inner and outer

In order to meet high accuracy and surface quality requirements, we offer cylindrical grinding of parts, both inner and outer.

Flat Grinding

When necessary, we apply flat grinding of parts. The size of the machine workspace is 500x250mm.

Surface treatment

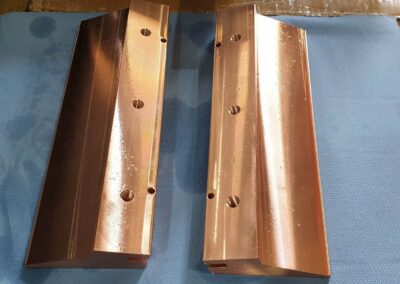

We offer to our customers different surface treatments of parts such as:

- Browning,

- Elox,

- Hard coat,

- Sandblast,

- Glass beads blasting,

- Galvanisation,

- Painting, etc

About Us

Who We Are

Our machining workshop was founded in 1983. Our core business activity is manufacture of parts according to customer requirements. We are specialised in production of small quantities, and single part orders. Send us Your drawing or a sample, and soon You will receive our competitive offer.

As a family owned business, we are strongly focused on human values and promote good atmosphere within the organisation. In order to provide consistent, and timely support to our customers, our workshop is continuously increasing personnel. By using of specialized training programs, the shop invests in qualification and skills. The experience, the competence and the motivation of employees make up the strong and reliable basis which ensures the success of our customers and the success of our workshop.

Our curiosity and imagination create solutions. Driven by desire for perfection, we offer customized solutions, as well as their professional realization within incomparable delivery periods.

Why Chose Us

• 34 years of experience

• Guaranteed quality

• Competitive Prices

• 80% Client retention rate

Our Guidelines

• Implementing of a quality management system.

• Continuously training our personell through training courses.

• Creating a safe place to work for all of our employees.

• Following the world trends in technology.

• Promoting good relationship with our partners.

Contact Us

Mobile: +38163561406

E-mail: bataada@gmail.com

Website: www.bata-ada.com

Bata Machining Workshop

Paje Radosavljevića 3, 24430 Ada, Serbia

Feel free to call us at any time or send us an email. And we are waiting you at our office for a personal meeting.

Please be patient while waiting for response.